Detailed Description

Stainless steel vertical pump In-Tank is compact and simple in design, having only one moving part, highly efficient with proven performance.

JK's stainless steel vertical pump is corrosion-resistant and all-purpose, ideal for many OEM wet processing applications. Whether you are pumping cleaners, caustics, salt solutions, chlorinated solvents, photographic chemicals, deionized water, fatty, phosphoric, citric, or lactic acids, they can be pumped with confidence. Maximum temperature ratings are primarily dependent on the elastomer employed and the vapour pressure of the liquid being pumped.

SUS316/SUS304# stainless steel vertical pumps utilize a replaceable coupled shaft using multiple set screws to minimize shaft deflection and misalignment associated problems while allowing the use of standard NEMA motors. They are readily available at most local motor suppliers, thus, saving prolonged downtime and money. Standard elastomers are EPR. Optional viton and PTFE elastomers are also available.

A motor stand-off and polytetrafluoroethylene (PTFE) slinger/disk provide optimum bottom motor bearing protection against chemical fume corrosiveness in the Penguin vertical in-tank pump. Single-phase motors are wired for 115 volts using a six-foot cord and grounding plug or for 230 volts using a six-foot cord without the plug. All 3phase motors are shipped unwired, whereby the direction of motor rotation must be determined by the end user prior to operation.

JKV 40 SK 1 5 V 6 Ti

1 2 3 4 5 6 7 8

| 1 | Model | JKV |

| 2 | In/outlet | 25-25*25 40-40*40 50-50*50 65-65*65 |

| 3 | S.G | SK-1.1 SP-1.4 |

| 4 | Power | 1/2HP, 1HP, 2HP, 3HP, 5HP, 7.5HP, 10HP |

| 5 | Frequency | 5-50HZ 6-60HZ |

| 6 | O-RING | E-EPDM V-VITON N-NBR |

| 7 | Material | 4-SUS304 6-SUS316 T-Ti |

| 8 | Shaft Material | SUS304 SUS316 Ti |

Recommended Applications

• OEMs

• Chemical Wet Processing

• Spray Rinse Pumping

• Wet Processing

• Stand-by Pumping

• Recirculating Pumping

• Fume Scrubbing

• Waste Treatment

• Filtering

• Water Treatment

• Plating/Etching

• Pump Stations

• Transfer Pumping

Stainless steel vertical pump Features

• Self-priming when immersed in the solution.

• In-tank mounted

• PTFE vapour seal

• Motor stand-off

• Added strength of stainless steel

Where are vertical pumps used?

1. Chemical liquid, recycling or transportation process, electroplating industry, chemical industry, leather, dyeing and finishing;

2. Waste liquids, acidic, industrial liquids and filtration purposes;

3. Printed circuit boards, semiconductors, electroplating processing, metal surface finishing, washing treatment, water treatment.

4. Cooling, spray washing equipment, waste gas tower, etching machine.

SPECIFICATION:

| MODEL | SG | IN/OUT | POWER | PHASE | 50HZ | 60HZ | ||

| HEAD(m) | FLOW(L/min) | HEAD(m) | FLOW(L/min) | |||||

| JKV-40SK-1 | 1:1 | 40*40 | 1 | 3 | 13 | 245 | 15 | 265 |

| JKV-40SK-2 | 1:1 | 40*40 | 2 | 3 | 15 | 305 | 17 | 305 |

| JKV-50SK-3 | 1:1 | 50*50 | 3 | 3 | 20 | 405 | 26 | 355 |

| JKV-50SK-5 | 1:1 | 50*50 | 5 | 3 | 28 | 485 | 28 | 505 |

| JKV-40SP-1 | 1.4 | 40*405 | 1 | 3 | 11 | 215 | 11 | 165 |

| JKV-40SP-2 | 1:4 | 40*40 | 2 | 3 | 14 | 265 | 14 | 265 |

| JKV-50SP-3 | 1:4 | 50*50 | 3 | 3 | 17 | 305 | 19 | 305 |

| JKV-50SP-5 | 1:4 | 50*50 | 5 | 3 | 22 | 425 | 25 | 455 |

| JKV-65SK-10 | 1:1 | 65*65 | 10 | 3 | 32 | 750 | 40 | 800 |

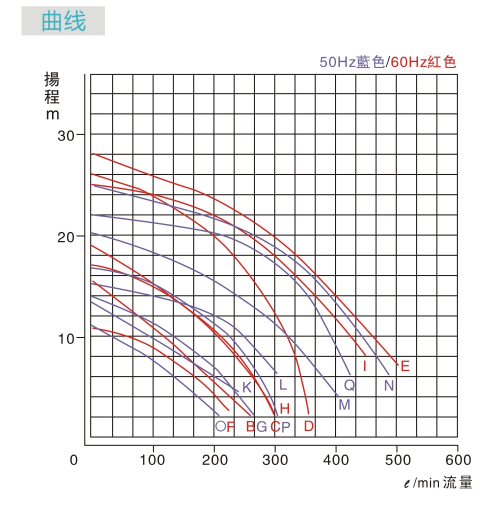

Performance Curve:

Dimension:

| MODEL | A | B | C | D | E | F | G | H | H1 | H2 | H3 | H4 | H5 | I | J | K | L | IN/OUTLET |

| JKV-25SK1/2 | 230 | 180 | 213 | 150 | 108 | 70 | ф15 | 534.5 | 199 | 60 | 225 | 239 | 23.5 | 78 | 78 | ф96 | ф94.5 | 25*25 |

| JKV-40SK-1 | 230 | 180 | 213 | 150 | 108 | 70 | ф15 | 559.5 | 199 | 60 | 250 | 239 | 23.5 | 78 | 78 | ф96 | ф94.5 | 40*40 |

| JKV-40SK-2 | 230 | 180 | 213 | 150 | 108 | 70 | ф15 | 574.5 | 199 | 60 | 265 | 239 | 23.5 | 78 | 78 | ф96 | ф94.5 | 40*40 |

| JKV-50SK-3 | 265 | 222 | 265 | 222 | 103.5 | 83 | ф15 | 743 | 301 | / | 350 | 341.5 | 14 | 97 | 97 | ф119 | ф119 | 50*50 |

| JKV-50SK-5 | 265 | 222 | 265 | 222 | 103.5 | 83 | ф15 | 763 | 301 | / | 370 | 341.5 | 14 | 97 | 97 | ф119 | ф119 | 50*50 |

PRODUCT FEATURES:

1. According to the needs of various chemical environments, different pump body materials can be selected:SUS304,SUS316,Ti;

2. The JKV series pumps are designed to run inside or outside the tank,however,the installation instructions should be followed;the vertical design has a maximum fluid temperature of 95℃;

3. Pumps are no damaged in dry running because of seal-less design,the pumps also are design with vapor seal O-ring and diversion groove;

4.Dry vapor seal ensure to prevent pumps are bearing from being etched by chemical gas and prolong the using life of pump.

5.Titanium material vertical pump suitable for special chemical liquid;

6.The stainless steel vertical pump application from chemical or water recirculation,waste treatment,plating solutions,PCB process,chemical recirculation;

7.For corrosive environment, it is recommended to use Titanium bolt and nuts and Epoxy paint on motor body to prolong motor lifespan;different brands motor of choice to your needs,for example:QUCHI,TECO ;

8.1 year warranty;

Recommended Applications:

• OEMS

• Chemical Wet Processing

• Spray Rinse Pumping

• Wet Processing

• Stand-by Pumping

• Recirculating Pumping

• Fume Scrubbing

• Waste Treatment

• Filtering

• Water Treatment

• Plating/Etching

• Pump Stations

• Transfer Pumping