MODEL INDENTIFICATION:

JKD-P - 50 - SP - 5 - 5 - V - U - Ti

1 2 3 4 5 6 7 8 9

| 1 | MODEL | JKD-P |

| 3 | IN/OUTLET | 20-32*20 ; 25-40*25 ; 50-50*40; 65-80*65 |

| 4 | SPECIFIC GRAVITY | SP-1.4 |

| 5 | POWER | ¼HP,½HP,1HP,2HP,3HP, 5HP, 7.5HP, 10-10HP |

| 6 | FREQUENCY | 5-50HZ 6-60HZ |

| 7 | O-RING | E-EPDM V-VITON N-NBR |

| 8 | MATERIAL | U- UPE(Ultra high molecular weight polyethylene) |

| 9 | SHAFT MATERIAL | 4-SUS304 6-SUS316 Ti-Ti |

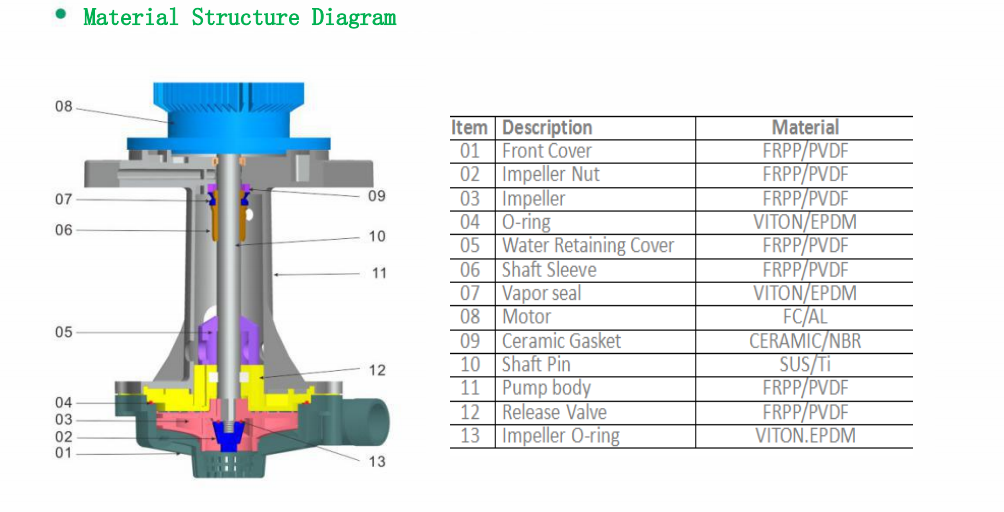

Detailed Description:

1. This product is our newly developed pump in 2019, material are manufactured from Ultra high molecular weight polyethylene(UPE),will can made the pump wear resistance,corrosion resistance,lifespan;

. Wear resistance ranks first in plastics, 7 times higher than carbon steel, 4 times higher than PTFE;

. Corrosion resistance: It can resist various corrosive media and organic solvent media within a certain temperature and humidity range, and has extremely high chemical stability;

.UPE's low temperature performance is excellent, and it is malleable at the temperature of liquid helium ;

.Widely used in the semiconductor industry;

2.Strong embedded impeller:High pressure;

3.The sand blasting vertical pump -JKD-P model for pumping chemical solution which contain dirt particles;

4.It is designed to installed in and outside tank and can be fitted together with filter system;

5.This model -JKD-P sand blasting vertical pump no damaged in drying-running;

6.For corrosive environment, it is recommended to use Titanium bolt and nuts and Epoxy paint on motor body to prolong motor lifespan;different brands motor of choice to your needs,for example:QUCHI,TECO and ABB;

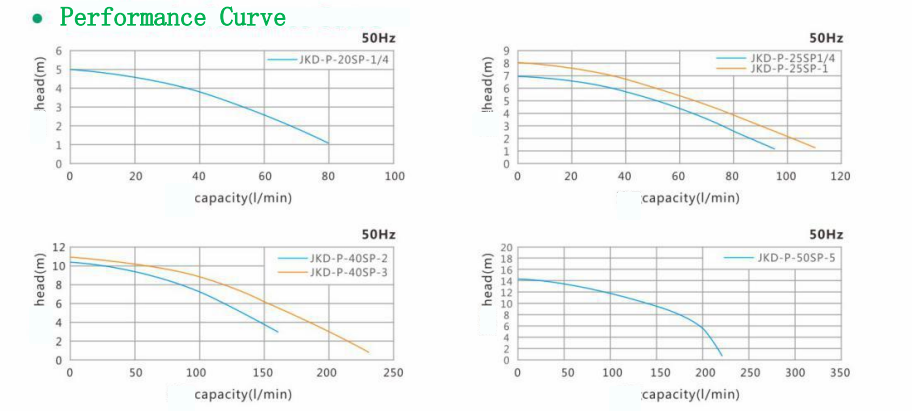

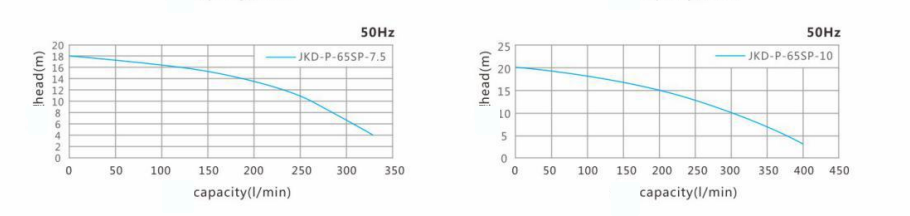

| MODEL | IN/OUTLET | 50HZ | POWER | |

| (mm) | MAX.HEAD(m) | MAX.CAP(L/min) | kw | |

| JKD-P-20SP¼ | 32*20 | 5 | 80 | 0.18 |

| JKD-P-25SP½ | 40*25 | 7 | 95 | 0.37 |

| JKD-P-25SP-1 | 40*25 | 8 | 110 | 0.75 |

| JKD-P-40SP-2 | 50*40 | 10.5 | 160 | 1.5 |

| JKD-P-40SP-3 | 50*40 | 11 | 230 | 2.2 |

| JKD-P-50SP-5 | 65*50 | 14.5 | 220 | 3.75 |

| JKD-P-65SP-7.5 | 80*65 | 18 | 330 | 5.5 |

| JKD-P-65SP-10 | 80*65 | 20 | 400 | 7.5 |

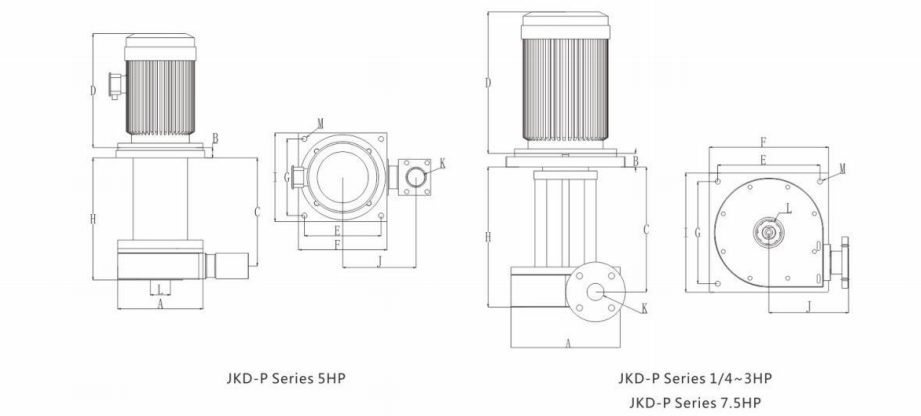

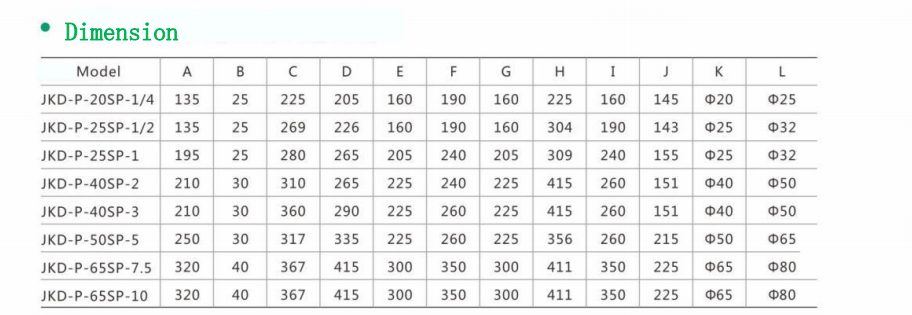

DIMENSION:

1. This product is our newly developed pump in 2019, material are manufactured from Ultra high molecular weight polyethylene(UPE),will can made the pump wear resistance,corrosion resistance,lifespan;

. Wear resistance ranks first in plastics, 7 times higher than carbon steel, 4 times higher than PTFE;

. Corrosion resistance: It can resist various corrosive media and organic solvent media within a certain temperature and humidity range, and has extremely high chemical stability;

.UPE's low temperature performance is excellent, and it is malleable at the temperature of liquid helium ;

.Widely used in the semiconductor industry;

2.Strong embedded impeller:High pressure;

3.The vertical chemical pump -JKD-P series widely used in high corrosive environment &acid chemical process such as etching,cooling circulating and plating;

4.It is designed to installed in and outside tank and can be fitted together with filter system;

5.This series vertical pump no damaged in drying-running;

6.For corrosive environment, it is recommended to use Titanium bolt and nuts and Epoxy paint on motor body to prolong motor lifespan;different brands motor of choice to your needs,for example:QUCHI,TECO and ABB;

JKD-P series sand blasting vertical pump for pumping chemical solution which contain dirt particles ;

Industry:Sewage industryl