M -V -P - 40 - SK - 1 - 5 - E - F - 4 - 4

1 2 3 4 5 6 7 8 9 10 11

| 1 | Model | M series |

| 2 | Type | Vertical pump |

| 3 | F-High flow P-High Pressure | |

| 4 | In/Outlet | 40-40*50 50-50*50 |

| 5 | SG | SK-1.1 SP-1.4 |

| 6 | Power | 1-0.75kw 2-1.5kw 3-2.2kw 5-3.75kw |

| 7 | Frequency | 5-50HZ 6-60HZ |

| 8 | O-ring | E -EPDM V -VITON |

| 9 | Material | F-FRPP P-PVDF |

| 10 | Shaft Length | 4-417 3-300 |

| 11 | Shaft Material | 4-SUS304 6-SUS316 T-Ti |

Detailed Description:

JK's new launched high pressure vertical pumps are design for those require high pressure with low motor horsepower.

Mvp series very efficient in performance when immersed in solution. Constructed completely of FRPP with PVDF wear ring, or FRPP with PVDF impeller or fully pvdf material where in contact with the solution, this vertical pump is suitable for pumping, agitating, filtering, or circulating acid and alkaline solutions, abrasive fluids, and other corrosive solutions up to 180C degrees maximum temperature.

Standard motors are 3 phase and totally enclosed fan cooled, with two part epoxy coating for additional corrosion resistance. A rigid, solid stainless steel rotor/drive shaft with an oversized bearing is employed to minimize shaft alignment problems, while allowing for quick and easy bearing replacement when required. The three phase motors are shipped unwired. A standard air purge/vent screw assembly in the bottom motor housing extends the life of the bottom motor bearing when utilizing minimal 5 psi air to create a positive displacement. An optional ceramic sealing sleeve is available for added corrosion resistance in preventing fumes and condensables from contacting the metallic shaft or impeller insert.

The new launched vertical pump-MVP series are versatile, easy to install, and require a minimal amount of tank space, thus saving valuable floor space.

Features:

• FRPP or PVDF Construction

• No Metal Contact

• Chemical Resistant

• Self-Priming When Immersed

• Run Dry Capability Without Damage

• Head to 30m

• Capacity to 550 L/min

Recommended Applications:

• Sump Pumping

• Transfer Pumping

• Recirculation Pumping

• Plating Solution Filtering

• Fume Scrubbing

• Waste Treatment

• Eductor Systems

• Other corrosive solutions

| Model | SG | In/Outlet(mm) | Max.Temperature(℃) | 50HZ | Power(kw) | ||

| FRPP | PVDF | Max.Head(m) | Max.Capacity(L/min) | ||||

| MVP-40SK-1 | 1.1 | 40*50 | 75℃ | 100℃ | 15 | 300 | 0.75 |

| MVP-40SK-2 | 1.1 | 40*50 | 75℃ | 100℃ | 22 | 380 | 1.5 |

| MVP-40SK-3 | 1.1 | 40*50 | 75℃ | 100℃ | 28 | 400 | 2.2 |

| MVP-50SK-5 | 1.1 | 50*50 | 75℃ | 100℃ | 30 | 550 | 3.75 |

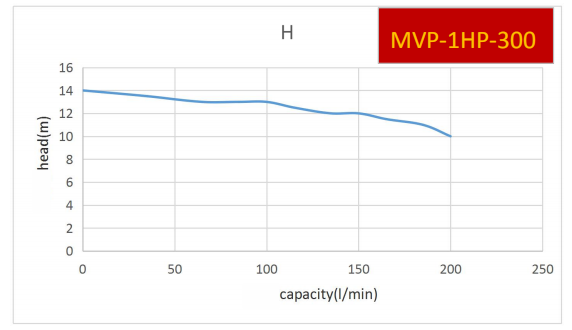

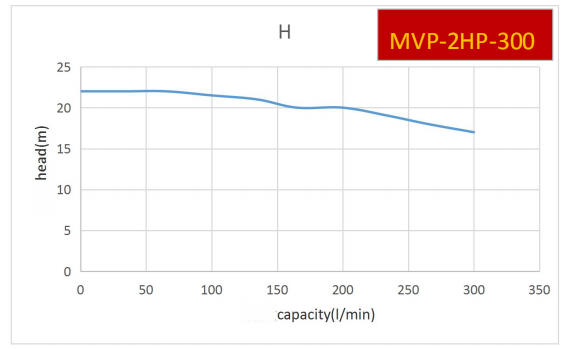

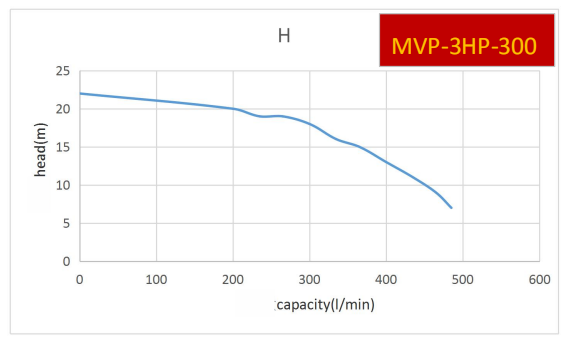

Performance Curve:

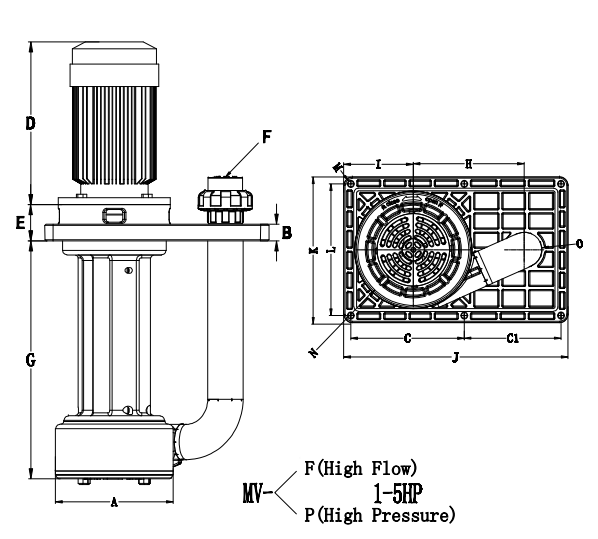

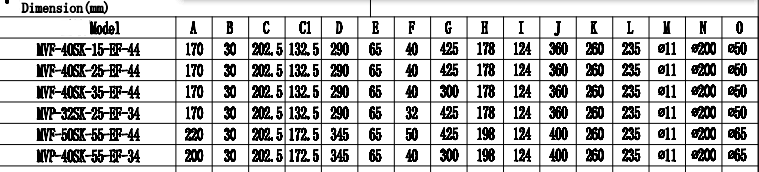

Dimension:

PRODUCT FEATURES:

1.New launched:MVP series for high pressure performance;

2.MVP series vertical pumps are manufactured from higher grade raw material and can be define to FRPP,PVDF for customer selection;

3.The vertical pump MVP series are designed to tun installed in the tank or process module,expect 1/8hp,1/6hp,all the test model have a slotted air gap in the pump base and a dry vapor seal ,there by preventing chemical penetrating to the motor bearing;

4.It is designed to inside tank and can be fitted together with filter system;the pump are used in a wide range of applications from chemical recirculation to process modules;

5.The weight of the pump is lighter,leak free operation and easy maintenance;

6.Vertical pumps can run dry without damage to vapor seal;

7.Max Operating Temperature: FRPP 75℃; PVDF:100℃;

8.For corrosive environment, it is recommended to use Titanium bolt and nuts and Epoxy paint on motor body to prolong motor lifespan;different brands motor of choice to your needs,for example:QUCHI,TECO and ABB;

9.1 year warranty;

Recommended Applications:

• Sump Pumping

• Transfer Pumping

• Recirculation Pumping

• Plating Solution Filtering

• Fume Scrubbing

• Waste Treatment

• Eductor Systems

• Other corrosive solutions