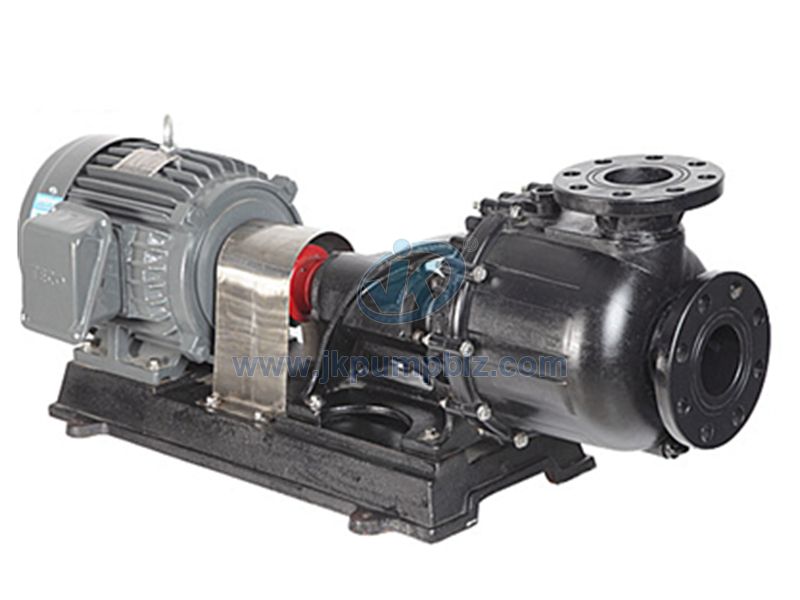

Self priming water pump detailed description

1. The material of pump body made from FRPP or PVDF suitable for chemical and corrosive environment.

2. It is designed with self priming vacuum, an extremely powerful self-priming force & built with a choke valve fully prevents liquid back-flow into the pump.

3. To protect the pump:

· To prevent foreign material from entering the suction inlet, foot valve should be installed at the inlet.

· To prevent immediate back-flow, check valve should be installed at the outlet.

· Back-flow into the pump can cause the pump’s body damage as well as dry-running.

4. Depending on customers’ needs, the cooling circulated tube can be assembled. The liquid inside the pump circulates and cools down the shaft seal especially during dry-running.

5.The self-priming centrifugal pump-JKB-L series best applicable to acid and alkaline chemical liquids, all polluted water treatment & etc.

MODEL INDENTIFICATION

JKB-L -F -75 -07 -2 -N -C -C -S -5

1 2 3 4 5 6 7 8 9 10

| 1 | MODEL | JKB-L |

| 2 | MATERIAL | F - FRPP P- PVDF |

| 3 | IN/OUTLET | 75-3" |

| 4 | POWER | 07-7.5HP, 10-10HP |

| 5 | POLE | 2-2P 4-4P |

| 6 | O-RING | N -VBR E -EPDM V -VITON |

| 7 | STATIONARY | C-CERAMIC S-SIC |

| 8 | ROTATIONAL RING | C-CARBON S-SIC |

| 9 | SPRING | SUS316 |

| 12 | FREQUENCY | 5-50HZ 6-60HZ |

Where to use the self priming pump?

1. Industrial self-priming pump is suitable for urban environmental protection, construction, fire protection, chemical, pharmaceutical, dye, printing and dyeing, brewing, electric power, electroplating, papermaking, petroleum, mining, equipment cooling, oil tanker unloading, etc.

2. Self-priming water pump is suitable for clean water, sea water, chemical medium liquid with acidity and alkalinity, and slurry with general paste. The viscosity of the medium is ≤100 CP, and the solid content can reach 30% or less.

3. It can be used with any type and specification of filter press, the most ideal matching pump type to send the slurry to the chemical filter housing.

4. Applications from water, fuels, effluent or”grey water”, right through to raw sewage, industrial wastewater and sewage sludge can be effectively handled by self priming centrifugal pumps.

Self priming pumps are mounted above the liquid source generally at “ground level”, so less infrastructure is required to set them up. And because they are located at ground level, they are easier to access and much easier to maintain and repair. As there is no mechanical equipment in the wet well, there is no need to open wet well lids, and there is no need for hoists or cranes as in the case of submersible pumps, making them a much safer option for operators.

Self priming water pump Maintenance

1. Check the inlet bottom valve or inlet filter to avoid clogging by impurities.

2. When the motor is running, pay attention to whether there is abnormal noise.

3. Check if there is any leakage.

4. If a check valve is installed, check whether its function is normal.

5. If there are a lot of crystals in the pump, the pump should be disassembled and disassembled, the impeller, pump body, and front cover should be soaked in acidic chemical solution and then reassembled in sequence, or the pump should be circulated in an acidic chemical solution. , And then clean it with clean water circulation.

6. Pay attention to several main parts when maintaining the pump: A. Rolling bearing: When the bearing is worn to a certain extent after the long-term operation, it must be replaced. B. Mechanical seal: Generally, the mechanical seal should not be disassembled for inspection when there is no leakage. If serious leakage occurs at the lower end of the bearing body, the mechanical seal should be disassembled and inspected. When assembling and disassembling the mechanical seal, it must be handled with care, pay attention to the cleaning of the mating surface, and protect the mirror surface of the static ring and the moving ring, and it is strictly prohibited to knock and collide.

Self priming pump Precautions

1. Check the motor power, including frequency, voltage range and wiring.

2. Check again to confirm that all parts (flange, base, etc.) have been securely fixed.

3. Check whether the height of the liquid level is appropriate, and do not drop below the liquid level at start up.

4. Check to make sure the inlet valve is open.

5. Rotate the motor cooling fan to ensure that it is not too tight or jammed.

6. Check whether the bolts are loose, whether the power cord and plug are in good condition, and make sure that the ground wire of the motor is in good contact.

Self priming pumps Post-maintenance

1. Under normal working conditions, the sewage pump should be filled or changed after every 300 hours of use, and the state of the mechanical seal components should be checked.

2. The disassembled and repaired sewage pump normally needs to be checked for air tightness in an environment of 0.2MPa.

3. After replacing the sealing ring: After the water pump enters the water, it is necessary to observe for a period of time. If the pumping capacity drops or the efficiency drops, the sewage pump should be removed, and the distance between the impeller part of the self-priming pump and the sealing ring should be checked;

4. Pay attention to several main parts when maintaining the acid and alkali resistant self-priming pump:

5. Rolling bearings: When the bearings are worn to a certain extent after long-term operation, they must be replaced.

6. Front sealing ring and rear sealing ring: When the sealing ring is worn to a certain degree, it must be replaced.

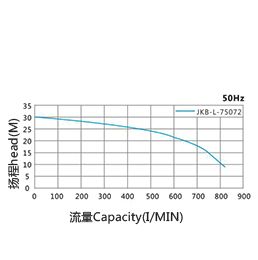

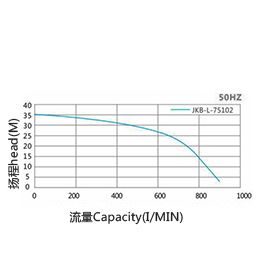

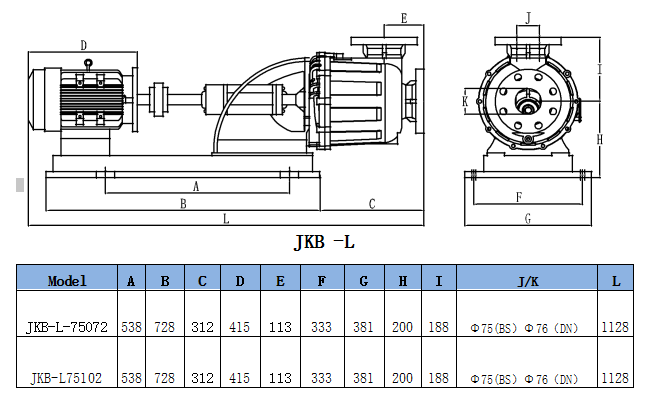

SPECIFICATION:

| MODEL | IN/OUT(mm) | POWER(HP) | PHASE | 50HZ | 60HZ | ||

| MAX HEAD(m) | MAX FLOW(L/min) | MAX HEAD(m) | MAX FLOW(L/min) | ||||

| JKB-L75072 | 75*75 | 7.5 | 3 | 30 | 820 | / | / |

| JKB-L75102 | 75*75 | 10 | 3 | 35.5 | 900 | / | / |

SELF PRIMING PUMP-JKB-L series Features:

1. The material of pump body made from FRPP or PVDF suitable for chemical and corrosive environment.

2. It is designed with self priming vacuum, an extremely powerful self priming force & built with a choke valve fully prevents liquid back-flow into the pump.

3. To protect the pump:-

· To prevent foreign material entering the suction inlet, foot valve should be installed at the inlet.

· To prevent from immediate back-flow, check valve should be installed at the outlet.

· Back-flow into the pump can cause pump’s body damage as well as dry-running.

4. Depending on customers’ needs, cooling circulated tube can be assembled. The liquid inside the pump circulates and cools down the shaft seal especially during dry-running.

5.The self priming centrifugal pump-JKB-L series best applicable to acid and alkaline chemical liquids, all polluted water treatment & etc.

The self priming centrifugal pump-JKB-L series best applicable to acid and alkaline chemical liquids, all polluted water treatment & etc.