MODEL INDENTIFICATION:

JKB F 75 10 2 N A H C C H 5

1 2 3 4 5 6 7 8 9 10 11 12

| 1 | MODEL | JKB |

| 2 | MATERIAL | F - FRPP P- PVDF |

| 3 | IN/OUTLET | 40-1.5", 50-2", 75-3" |

| 4 | POWER | 00-½, 01-1HP,02-2HP, 03-3HP,05-5HP, 07-7.5HP, 10-10HP |

| 5 | POLE | 2-2P 4-4P |

| 6 | O-RING | N -NBR E -EPDM V -VITON |

| 7 | A-WITH CHECK VALVE(INLET HIGHER THAN LIQUID LEVEL)B-NON CHECK VALVE(INLET LOW THAN LIQUID LEVEL) | |

| 9 | STATIONARY RING | C-CERAMIC S-SIC |

| 10 | ROTATIONAL RING | C-CARBON S-SIC |

| 11 | SPRING | SUS316 |

| 12 | FREQUENCY | 5-50HZ 6-60HZ |

Self priming centrifugal pump-JKB series detailed introdduction:

The centrifugal pump that can automatically pump water up without filling the suction pipe with water has a smart structure and is easy to disassemble. It is a widely used type of acid and alkali resistant self priming pump.

working principle:

Horizontal self-priming pump is a kind of centrifugal pump equipment. The pump body is composed of suction chamber, liquid storage chamber, scroll chamber, liquid return hole, gas-liquid separation chamber, etc. The basic principle is that the pump is filled before starting After the pump is started, due to the centrifugal force of the impeller of the self-priming pump, the gas-liquid mixture is continuously thrown out, flows along the volute of the self-priming pump, and is sent to the discharge port. A gas-liquid separation chamber with a wide cross-section is provided at the liquid discharge port, so after the mixed liquid enters the gas-liquid separation chamber, the gas is separated and escaped, and is discharged from the liquid discharge pipe and the exhaust pipe. The degassed liquid flows back to the impeller inlet along the outer passage of the pump body due to its high specific gravity, and mixes the air again to form a mixed liquid. In this way, the liquid is continuously sucked and discharged from the pump body under the action of atmospheric pressure and negative pressure in the pump.

Features:

A. The self priming cylinder and the pump body are integrally formed with no solder joints and no leakage

B. The middle cover is integrally formed and adopts a "reinforced rib" structure with long service life

C. High-efficiency impeller design, integrated molding, improve pump efficiency and service life

D. Self-priming cylinder and flange are integrally formed, high pressure resistance, strong external force resistance, no leakage, and long service life

E. The rear cover, shaft seal guard and tripod can be disassembled for maintenance

Application:

Electroplating, electronics, chemical industry, leather, dyeing and finishing, waste water, waste gas and other chemical liquid conditions that need to be transported.

Maintenance:

1. Check the inlet bottom valve or inlet filter to avoid clogging by impurities.

2. When the motor is running, pay attention to whether there is abnormal noise.

3. Check if there is any leakage.

4. If a check valve is installed, check whether its function is normal.

5. If there are a lot of crystals in the pump, the pump should be disassembled and disassembled, the impeller, pump body, and front cover should be soaked in acidic chemical solution and then reassembled in sequence, or the pump should be circulated in acidic chemical solution. , And then clean it with clean water circulation.

6. Pay attention to several main parts when maintaining the pump: A. Rolling bearing: When the bearing is worn to a certain extent after long-term operation, it must be replaced. B. Mechanical seal: Generally, the mechanical seal should not be disassembled for inspection when there is no leakage. If serious leakage occurs at the lower end of the bearing body, the mechanical seal should be disassembled and inspected. When assembling and disassembling the mechanical seal, it must be handled with care, pay attention to the cleaning of the mating surface, and protect the mirror surface of the static ring and the moving ring, and it is strictly prohibited to knock and collide.

SPECIFICATION:

| MODEL | IN/OUT(mm) | POWER(HP) | PHASE | 50HZ | 60HZ | ||

| MAX HEAD(m) | MAX FLOW(L/min) | MAX HEAD(m) | MAX FLOW(L/min) | ||||

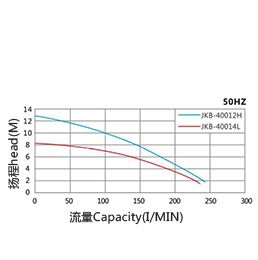

| JKB-40012L | 40*40 | 1 | 3 | 12.8 | 244 | 16 | 240 |

| JKB-40014L | 40*40 | 1 | 3 | 8.2 | 236 | 10 | 270 |

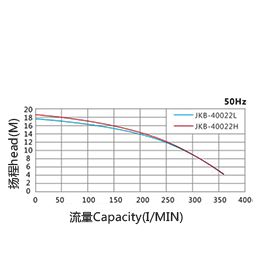

| JKB-40022L | 40*40 | 2 | 3 | 17.4 | 360 | 21 | 320 |

| JKB-40022H | 40*40 | 2 | 3 | 18.5 | 360 | 25 | 350 |

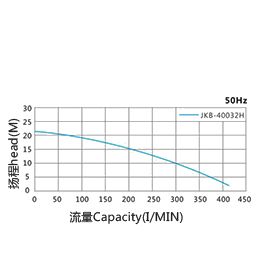

| JKB-40032H | 40*40 | 3 | 3 | 22.5 | 410 | 28 | 400 |

| JKB-50032L | 50*50 | 3 | 3 | 21.5 | 380 | 21.6 | 340 |

| JKB-50032H | 50*50 | 3 | 3 | 23 | 410 | 30 | 420 |

| JKB-50052H | 50*50 | 5 | 2 | 25 | 650 | 35 | 540 |

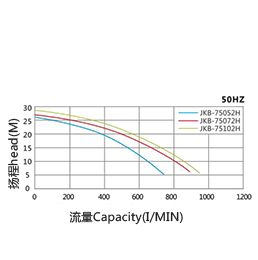

| JKB-75052H | 75*75 | 5 | 2 | 26 | 750 | 34 | 660 |

| JKB-75072H | 75*75 | 7.5 | 2 | 27 | 900 | 38.5 | 980 |

| JKB-75102H | 75*75 | 10 | 2 | 28.5 | 960 | 40 | 1050 |

SELF PRIMING PUMP-JKB series Features:

1.The material of pump body made from FRPP or PVDF suitable for chemical and corrosive environment.

2.It is designed with self priming vacuum, an extremely powerful self priming force & built with a choke valve fully prevents liquid back-flow into the pump.

3.To protect the pump:-

To prevent foreign material entering the suction inlet, foot valve should be installed at the inlet.

To prevent from immediate back-flow, check valve should be installed at the outlet.

Back-flow into the pump can cause pump’s body damage as well as dry-running.

4.Depending on customers’ needs, cooling circulated tube can be assembled. The liquid inside the pump circulates and cools down the shaft seal especially during dry-running.

5.The self priming centrifugal pump -JKB series best applicable to acid and alkaline chemical liquids, all polluted water treatment & etc.

The self priming centrifugal pump -JKB series best applicable to acid and alkaline chemical liquids, all polluted water treatment & etc.