MODEL INDENTIFICATION

| JMX | F | 44 | 0 | C | C | V | 5 |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 1 | MODEL | JMX |

| 2 | MATERIAL | F - FRPP P- PVDF C -CFRPP E- ETFE A -PFA |

| 3 | IN/OUTLET | 25-25*25 44-40*40 45-40*50 |

| 4 | POWER | 0-1/2HP 1-1HP 2-2HP 3-3HP 5-5HP |

| 5 | SPINDLE | C- CERAMIC S -SSIC |

| 6 | BEARING | C-CARBON S-SSIC |

| 7 | O-RING | N- NBR E- EPDM V- VITON |

| 8 | FERQUENCY | 5 -50HZ 6 -60HZ |

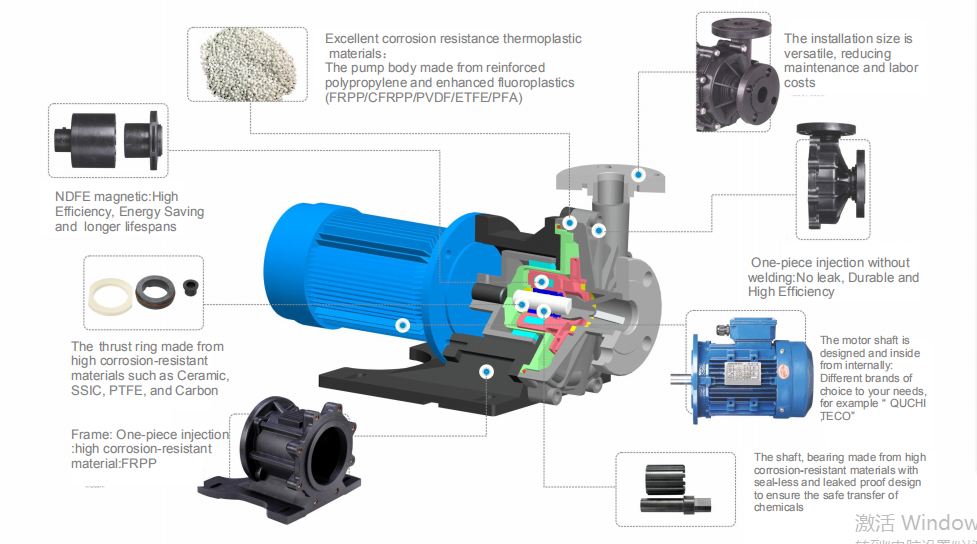

Magnetic drive pump JMX series features:

1. Outstanding Acid /Alkaline resisting capability:

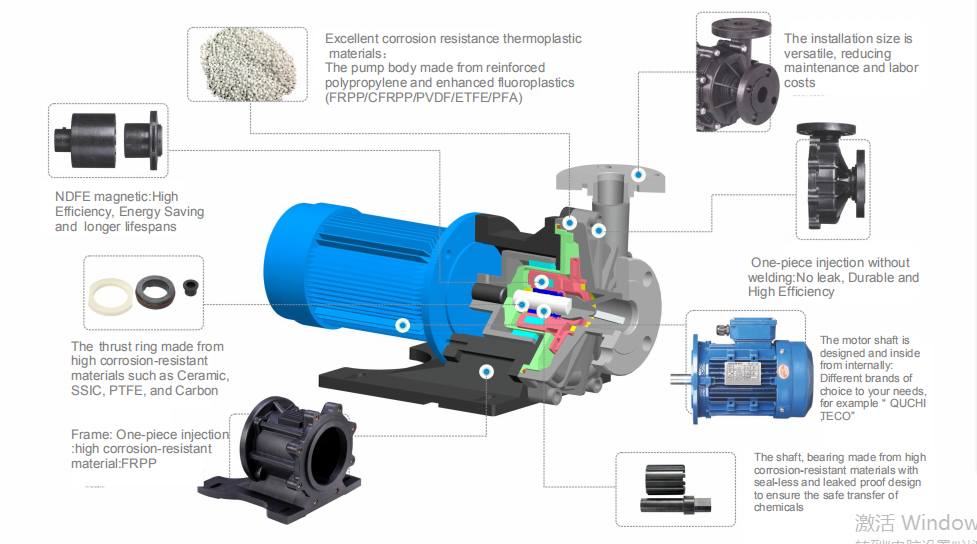

Excellent corrosion resistance thermoplastic materials of pump body has 5 kinds ,including FRPP,CFRPP,PVDF.ETFE,PFA;

FRPP/CFRPP material can resist temperature up to 75℃,

PVDF/ETFE/PFA material can resist temperature up to 90℃;

2. Due to the unique impeller bearing housing design,even the pump dry-running,the temperature inside pump head won’t easily increase to prevent pump for damaged &jam;

3. Corrosion resisting:seal-less and leaked proof design to ensure the safe transfer of chemicals;

The parts of the pump spindle can be made from ceramic and SIC;

The ceramic spindle is generally applied for low corrosion liquid;

The SIC spindle is excellent for high corrosion liquid;

4.One piece injection without welding “No leak, Durable and High Efficiency”;

The pump body is seal completely to prevent liquid leakage and hence preventing pollution or corrosion problems caused by many traditional mechanical seal pump. Besides that, the pump's impeller and magnetic parts integrate well to avoid damage during high-speed rotation and high temperature. The integrated impeller and inner magnet also reduce the assembly risk and therefore increase the efficiency of the pump;

5. Impeller and magnet capsule,although the pump dry-running,the temperature cannot be get higher quickly to avoid pump be damaged seriously;

6.The motor is equipped with temperature protection which avoids motor damaged due to high temperature caused by overload;

The motor shaft is designed and inside from intermally;

We have different motor brands of choice to your needs,for example “QUCHI,TECO” ;

7.Easy to assembly and maintenance:Most of the pump's parts are moulded design for easy to assemble and maintain;

8. One piece injection frame :High corrosion-resistant,material made from FRPP/PVDF;

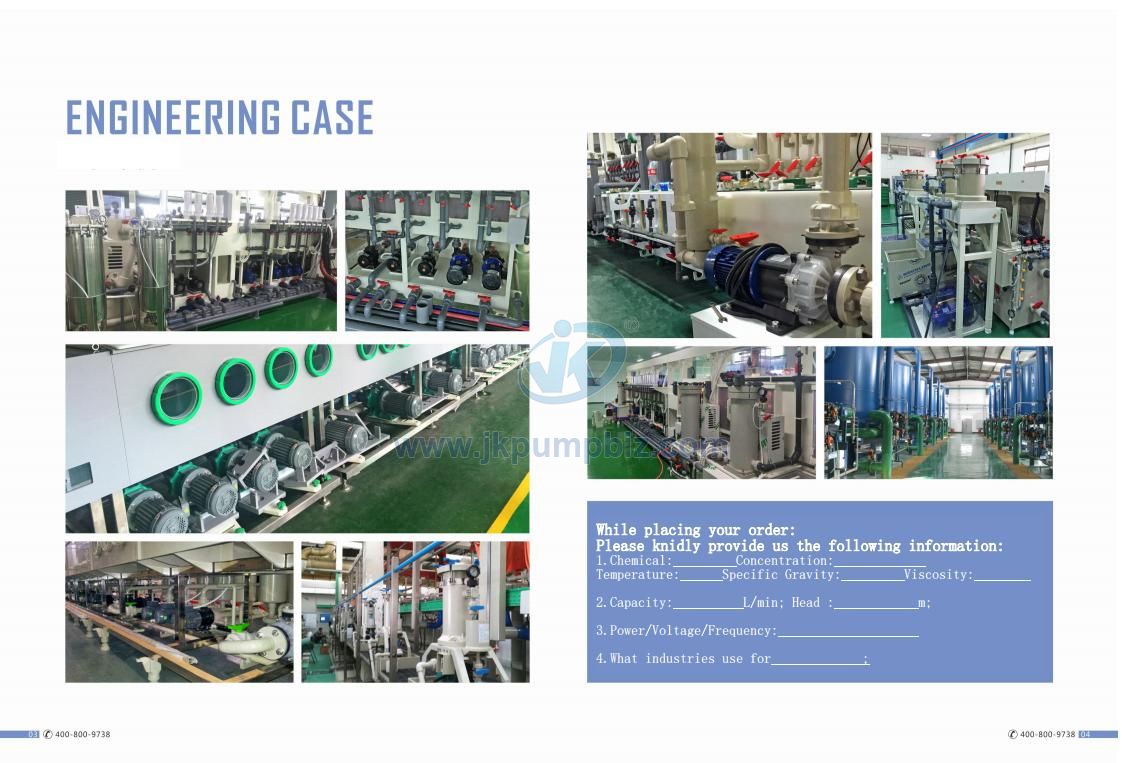

9. The magnetic drive chemical pump JMX series are highly recommended for use in various production processes,such as filtering, PCB,spraying,washing,plating,chemical transfer / blending ,and etching in surface treatment applications;

10.Can be used with chemical filter housing;

What are the magnetic pump application:

The magnetic drive pump JMX series, widely used in electroplating, painting, waste gas, waste water treatment, etching, PCB circuit board, electronics manufacturing, chemical industry, leather, dyeing and finishing, etc;

It is used for the transportation of acid and alkali media with no leakage characteristics.

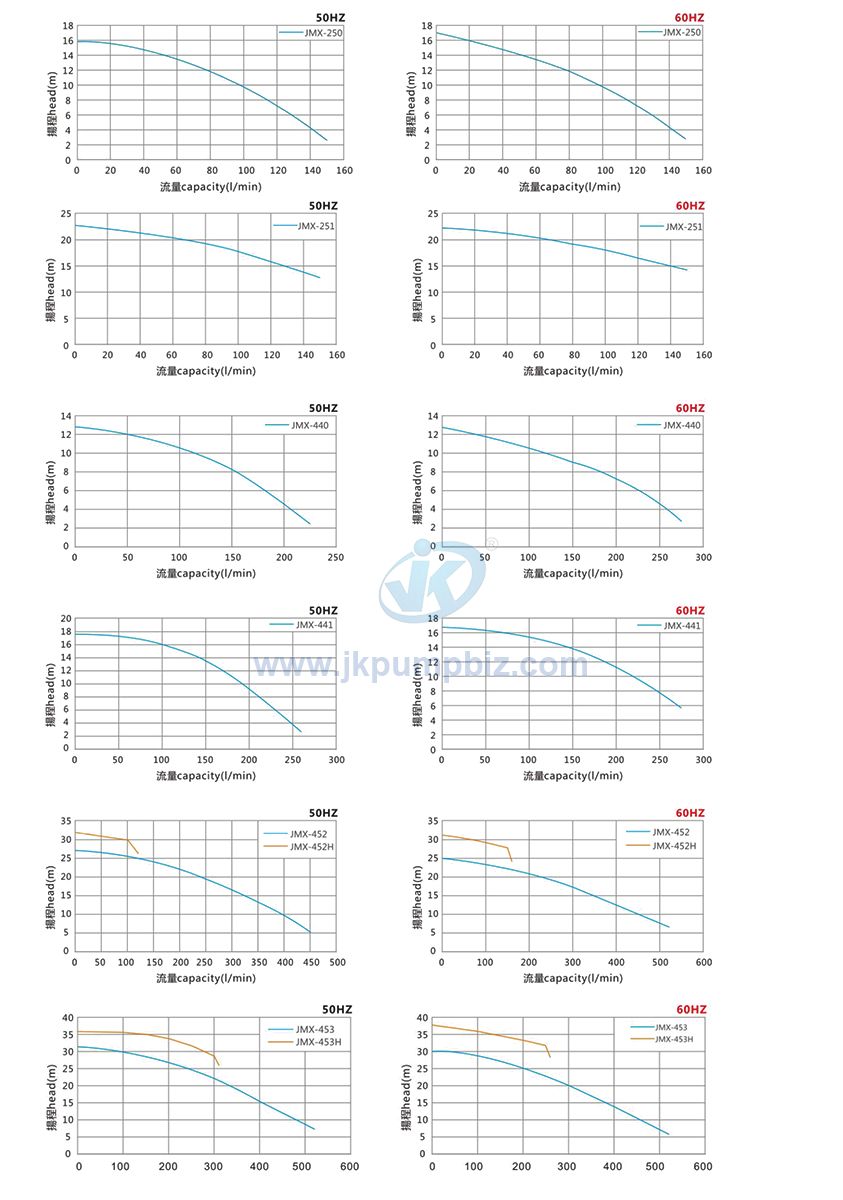

SPECIFICATIONS:

| MODEL | IN/OUT | POWER | 50HZ | 60HZ | ||

| MAX HEAD(m) | MAX FLOW(L/min) | MAX HEAD(m) | MAX FLOW(L/min) | |||

| JMX250 | 25*25 | 0.37 | 15.8 | 150 | 17 | 153 |

| JMX251 | 25*25 | 0.75 | 22.8 | 150 | 22 | 153 |

| JMX440 | 40*40 | 0.37 | 12.8 | 225 | 12.8 | 275 |

| JMX441 | 40*40 | 0.75 | 17.6 | 260 | 16.8 | 275 |

| JMX452 | 50*40 | 1.5 | 26.9 | 450 | 25 | 520 |

| JMX452H | 50*40 | 1.5 | 32 | 120 | 32 | 160 |

| JMX453 | 50*40 | 2.2 | 31 | 520 | 30 | 520 |

| JMX453H | 50*40 | 2.2 | 35.8 | 310 | 37.5 | 260 |

Performance Curve:

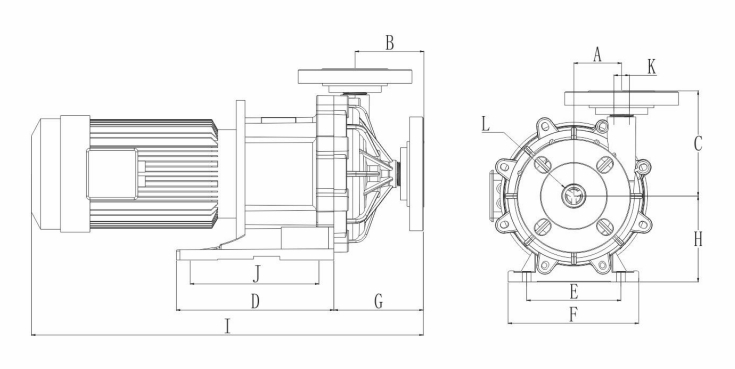

Dimension:

| MODEL | A | B | C | D | E | F | G | H | I | J | K | L |

| JMX-250 | 67 | 90 | 140 | 204 | 146 | 191 | 120 | 115 | 447 | 133 | Ф25 | Ф25 |

| JMX-251 | 67 | 90 | 140 | 204 | 146 | 191 | 120 | 115 | 559 | 133 | Ф25 | Ф25 |

| JMX-440 | 57 | 87 | 130 | 198 | 133 | 159 | 112 | 112 | 447 | 130 | Ф40 | Ф40 |

| JMX-442 | 70 | 102 | 140 | 215 | 108 | 192 | 130 | 112 | 512 | 130 | Ф40 | Ф40 |

| JMX-452 | 80 | 90 | 162 | 276 | 210 | 263 | 121 | 120.5 | 512 | 202 | Ф40 | Ф50 |

| JMX-452H | 80 | 90 | 162 | 276 | 210 | 263 | 121 | 120.5 | 512 | 202 | Ф40 | Ф50 |

| JMX-453 | 80 | 90 | 162 | 276 | 210 | 263 | 121 | 120.5 | 535 | 202 | Ф40 | Ф50 |

| JMX-453H | 80 | 90 | 162 | 276 | 210 | 263 | 121 | 120.5 | 535 | 202 | Ф40 | Ф50 |

Magnetic drive pump JMX series Features:

1. Outstanding Acid /Alkaline resisting capability:

Excellent corrosion resistance thermoplastic materials of pump body has 5 kinds ,including FRPP,CFRPP,PVDF.ETFE,PFA;

FRPP/CFRPP material can resist temperature up to 75℃,

PVDF/ETFE/PFA material can resist temperature up to 90℃;

2. Due to the unique impeller bearing housing design,even the pump dry-running,the temperature inside pump head won’t easily increase to prevent pump for damaged &jam;

3. Corrosion resisting:seal-less and leaked proof design to ensure the safe transfer of chemicals;

The parts of the pump spindle can be made from ceramic and SIC;

The ceramic spindle is generally applied for low corrosion liquid;

The SIC spindle is excellent for high corrosion liquid;

4.One piece injection without welding “No leak, Durable and High Efficiency”;

The pump body is seal completely to prevent liquid leakage and hence preventing pollution or corrosion problems caused by many traditional mechanical seal pump. Besides that, the pump's impeller and magnetic parts integrate well to avoid damage during high-speed rotation and high temperature. The integrated impeller and inner magnet also reduce the assembly risk and therefore increase the efficiency of the pump;

5. Impeller and magnet capsule,although the pump dry-running,the temperature cannot be get higher quickly to avoid pump be damaged seriously;

6.The motor is equipped with temperature protection which avoids motor damaged due to high temperature caused by overload;

The motor shaft is designed and inside from intermally;

We have different motor brands of choice to your needs,for example “QUCHI,TECO” ;

7.Easy to assembly and maintenance:Most of the pump's parts are moulded design for easy to assemble and maintain;

8. One piece injection frame :High corrosion-resistant,material made from FRPP/PVDF;

9. The magnetic drive chemical pump JMX series are highly recommended for use in various production processes,such as filtering, PCB,spraying,washing,plating,chemical transfer / blending ,and etching in surface treatment applications;

10.Can be used with chemical filter housing;

Our Pumps are specifically designed for Waste Water Treatment, Chemical Industry, Electroplating Industry, Scrubber, City Water Supply and Metal Industry;