What is rectifier?

The rectifier is used for electrolysis, electroplating, electrophoresis processing, as a power supply equipment. It is mainly a machine that adjusts the current and voltage of the standard input power supply.

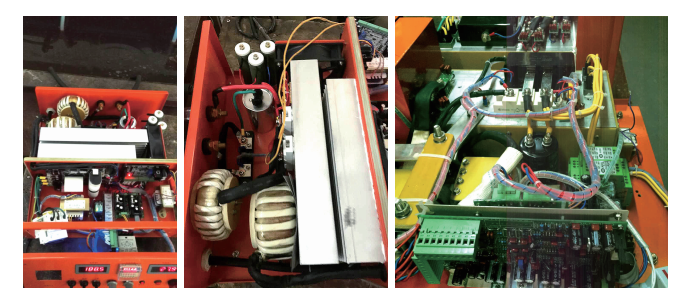

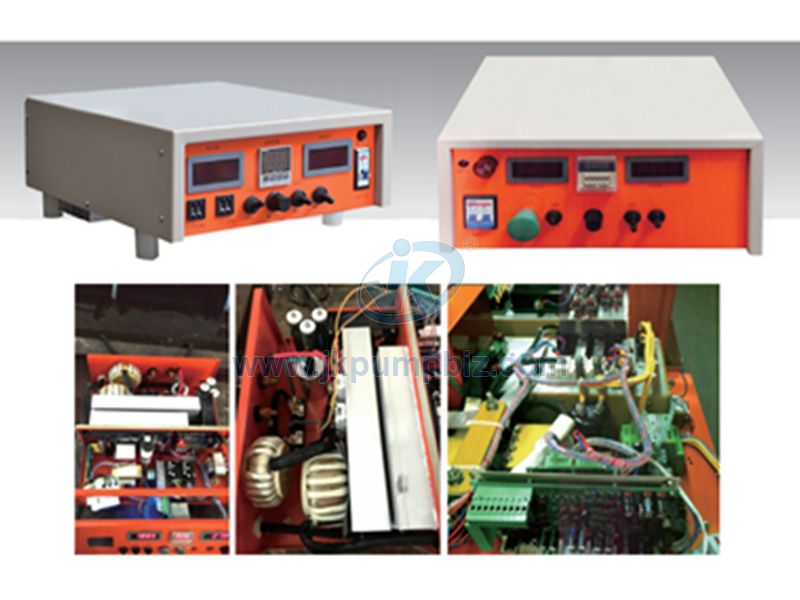

Electroplating rectifier is also as switching power supply or high-frequency switching power supply. It uses ultra-microcrystalline (also known as nanocrystalline) soft magnetic alloy material as the main transformer core and imported IGBT as the main power device. The main control system adopts multi-loop control. Technical and structural measures are taken to prevent salt spray acidification. The power supply has a reasonable structure and strong reliability. The power supply has become an updated product of the SCR power supply due to its small size, light weight, high efficiency and high reliability.

What is switching power supply for air cooling used for?

Electroplating rectifier for air cooling is suitable for continuous electroplating, precious metal electroplating, precision electroplating, PCB electroplating, surface treatment of jewelry and small hardware objects and other areas that require very low ripple;

Features:

High frequency, small size and light weight.

The ripple coefficient is low (<1%), and it has a very good performance on the uniformity of the coating.

·For high aspect ratio (through holes, blind holes, and filling holes with strong distribution force).

·Stabilization, steady flow control mode.

Special internal structure, suitable for various harsh environments.

It can be directly equipped with RS485 control to realize full digital network transmission.

·The internal circuit board adopts anti-salt spray acidification three-proof glue, so that the electronic components are not easy to be corroded by the environment.

For example:500A 12v air cooling plating electrowinning DC rectifier:

| Specifications for rectifier GH50012(500A 12V) | ||

| 1 | Cooling Method | Air cooled |

| 2 | Control Mode | Remote control |

| 3 | AC Input | Single-phase,220V(Adjustable) |

| 4 | Frequency | 50HZ/60HZ |

| 5 | Output(V) | DC 0-12V |

| 6 | Anpere | 0-500A |

| 7 | Output power | 6000W |

| 8 | Output Wavefom | Square/Flat(Ripple coefficient) |

| 9 | Efficiency | >92% |

| 10 | Adjustment Accuracy | <0.5% |

| 11 | Stable Accuracy | <0.5% |

| 12 | Machine output protection | Equipped with load, current limit, overheat, over voltage, alarm protection, electrolytic abnormal protection |

| 13 | Fault Alarm System | Acousto-optic alarm, flashing and beating when a fault occurs, the fault can be found immediately |

| 14 | Environmental Requirements | Temperature:>35%, humidity:>90%, no conductive explosion dust, no corrosive metal and damage |

The function of the PLC:

1. PLC control function, through PLC to control the rectifier.

2. The rectifier is controlled by RS485 communication, and it can be controlled by PLC and rectifier communication.

3. The control function can be displayed through the PLC touch screen, and the employees can complete various operations through the touch screen.

1. The PLC modules that need to be added are the CPU module and the communication module.

2. RS485 communication control function of the rectifier. 1) On the basis of the current rectifier, the RS485 automatic communication control board is added, and the rectifier can be controlled by the way of communication between the PLC and the rectifier.

3. Touch screen display control function. The system is equipped with a 10-inch touch screen to display various parameters of the device. At the same time, the current/voltage parameters of the rectifier can be set through the touch screen control.

4. The powerful database function of computer monitoring software can be used to record a large number of various production process parameters, current alarms and other records for a long time, which is convenient for data query.

Specification:The special specifications custom-made according to the customer:

| Model | Output current(A) | Output Voltage(V) | Power(KW) | Input current(A) | Output | Weight(kg) | Size(mm) |

| GH10012 | 100A | 12V | 1.2KW | 12A | 220V | 17 | 420*420*180 |

| GH10024 | 100A | 24V | 2.4KW | 12A | 220V | 20 | 420*420*180 |

| GH20012 | 200A | 12V | 2.4KW | 12A | 220V | 20 | 420*420*180 |

| GH20024 | 200A | 24V | 4.8KW | 8A | 380V | 40 | 450*500*225 |

| GH20024 | 200A | 24V | 4.8KW | 8A | 380V | 40 | 450*500*225 |

| GH20036 | 200A | 36V | 7.2KW | 12A | 380V | 40 | 450*500*225 |

| GH20048 | 200A | 48V | 9.6KW | 16A | 380V | 40 | 450*500*225 |

| GH30012 | 300A | 12V | 3.6KW | 18A | 220V | 20 | 420*420*180 |

| GH30024 | 300A | 24V | 7.2KW | 12A | 380V | 40 | 450*500*225 |

| GH30036 | 300A | 36V | 10.8KW | 18A | 380V | 40 | 450*500*225 |

| GH30048 | 300A | 48V | 14.4KW | 24A | 380V | 95 | 510*580*690 |

| GH33030 | 330A | 30V | 9.9KW | 16.5A | 380V | 40 | 450*500*225 |

| GH40030 | 400A | 30V | 12KW | 20A | 380V | 40 | 450*500*225 |

| GH50012 | 500A | 12V | 6KW | 10A | 380V | 25 | 420*450*220 |

| GH50024 | 500A | 24V | 12KW | 20A | 380V | 40 | 450*500*220 |

| GH50036 | 500A | 36V | 18KW | 30A | 380V | 50 | 510*580*690 |

| GH50048 | 500A | 48V | 24KW | 40A | 380V | 60 | 510*580*690 |

| GH100012 | 1000A | 12V | 12KW | 20A | 380V | 45 | 450*550*320 |

| GH100024 | 1000A | 24V | 24KW | 40A | 380V | 95 | 510*580*650 |

| GH100036 | 1000A | 36V | 36KW | 60A | 380V | 130 | 510*580*920 |

| GH100048 | 1000A | 48V | 48KW | 80A | 380V | 130 | 510*580*920 |

| GH200024 | 2000A | 12V | 24KW | 40A | 380V | 90 | 510*580*680 |

| GH200024 | 2000A | 24V | 48KW | 80A | 380V | 130 | 510*580*920 |

| GH300012 | 3000A | 12V | 36KW | 55A | 380V | 100 | 510*250*920 |

| GH400012 | 4000A | 12V | 48KW | 73A | 380V | 130 | 510*580*1150 |

| GH500012 | 5000A | 12V | 60KW | 90A | 380V | 150 | 530*600*1600 |

| GH1800016 | 18000A | 16V | 288KW | 480A | 380V | 500 | 800*1350*2100 |

For example:500A 12v air cooling plating electrowinning DC rectifier:

| Specifications for rectifier GH50012(500A 12V) | ||

| 1 | Cooling Method | Air cooled |

| 2 | Control Mode | Remote control |

| 3 | AC Input | Single-phase,220V(Adjustable) |

| 4 | Frequency | 50HZ/60HZ |

| 5 | Output(V) | DC 0-12V |

| 6 | Anpere | 0-500A |

| 7 | Output power | 6000W |

| 8 | Output Wavefom | Square/Flat(Ripple coefficient) |

| 9 | Efficiency | >92% |

| 10 | Adjustment Accuracy | <0.5% |

| 11 | Stable Accuracy | <0.5% |

| 12 | Machine output protection | Equipped with load, current limit, overheat, over voltage, alarm protection, electrolytic abnormal protection |

| 13 | Fault Alarm System | Acousto-optic alarm, flashing and beating when a fault occurs, the fault can be found immediately |

| 14 | Environmental Requirements | Temperature:>35%, humidity:>90%, no conductive explosion dust, no corrosive metal and damage |

1.Working principle of high frequency switching power supply:

The high-frequency switching power supply is rectified by the rectifier bridge and chopped with a high-frequency switch tube. After the transformer is transformed, it is rectified and filtered to obtain DC. A pulse width modulator (PWM) device controls the on and off time of the switch tube to achieve the purpose of voltage regulation.

2.Energy saving:

High-frequency switching power supply has more advantages than silicon controlled rectifiers in the application field of low voltage and large current. The most obvious is energy saving and power saving, which is mainly manifested in the following aspects;

(1) The power frequency transformer used in the main transformer of the silicon rectifier is not only cumbersome, but also very power hungry. For a six-phase half-wave rectifier transformer, its loss is generally 5% of the total power when rated, while the main high-frequency switching power supply The high-frequency transformer used in the transformer has a small size and the loss is generally within 1%;

(2) The diode of the high-frequency switching power supply uses a Schottky diode with a voltage drop of only 0.6V, and the loss of the silicon controlled rectifier is generally above 1V. For low-voltage high-current power supplies, the loss of the silicon controlled rectifier is in addition to the transformer The main loss outside, the other primary loss is very small due to the small power;

Therefore, the high-frequency switching power supply has received at least 5% of the energy-saving rating of the thyristor. As the voltage and current decrease, the proportion of energy saving will gradually increase;

Example: When a 20000A15V high-frequency switching power supply and a thyristor rectifier are running at rated power, according to the minimum energy loss of 5% calculation, a high-frequency switching power supply can save at least W=(20000* than thyristor rectifier) 15/0.85)-(20000*15/0.9) ≈ 15KW, according to 12 hours a day, 365 days of energy savings per year Q=15*12*365=65700KW*H, calculated according to 0.8 yuan per KW*H, At least 52560 yuan/unit can be saved every year;

3.Strong anti-interference ability;

Both the high-frequency switching power supply and the silicon controlled rectifier have the problem of radiation interference. When the silicon controlled rectifier triggers the thyristor to turn on, there is the problem of radiation interference. Because the high-frequency switching power supply of the power source uses soft switching technology Thereby effectively reducing radiated interference;

4.Both the high-frequency switching power supply and the silicon controlled rectifier have the problem of radiation interference. When the silicon controlled rectifier triggers the thyristor to turn on, there is the problem of radiation interference. Because the high-frequency switching power supply of the power source uses soft switching technology Thereby effectively reducing radiated interference;

5.The above specifications are available all the time,but we can have the special specifications custom-made according to the customers;

5.1 year warranty;

6.All products are manufactured in accordance with ISO9001 production standard to assure best quality ;

7.Suitable for continuous electroplating, precious metal electroplating, precision electroplating, PCB electroplating, jewelry and small hardware surface treatment and other fields requiring low ripple;

Features:

High frequency, small size and light weight;

Low ripple factor, outstanding performance on the uniformity of the coating;

Strong distribution force for high aspect ratio, through holes, and blind holes;

Voltage stabilization, steady current, control mode;

Special structure, suitable for various harsh environments;

Can be directly equipped with RS485 control to realize digital network transmission;

The internal circuit board adopts anti-salt spray acid-proof three-proof glue, so that electronic components are not susceptible to environmental corrosion;