MODEL INDENTIFICATION:

JL - 2001 - F - F - N - B - J - S

1 2 3 4 5 6 7 8

| 1.MODEL | JL |

| 2.CORE NUMBER | 1001-10"×1PCS,2001-20"×1PCS1004-10"×4PCS,2004-20"×4 PCS,2006-20"*6PCS,2008-20"*8PCS, 2012-20"*12PCS,2018-20"*18PCS,3018-30"*18PCS |

| 3.MATERIAL OF FILTER BODY | F FRPP P -PVDF T-Transparent acrylic |

| 4.TYPE OF IN/OUTLET | U-UNION F-FLANGE |

| 5.MATERIAL OF SEAL PACKING | N- NBR V -VITON |

| 6.TYPE OF FILTER CORE | C-Pressure core filter B- Lock core filter T- Pressure layered core filter K-Bellow filter P-Paper filter U-Bag filter |

| 7.SPECIFICATION OF IN/OUTLER | J -JIS D- DIN A- ANSI |

| 8.MATERIAL OF CLAMP | S-SUS316 T--Ti(Titanium) |

| 9.WITH FRPP STAND OR WITHOUT STAND | |

What is a chemical filter?

Chemical filters are utilities that separate substances in a flow from each other. Chemical filters can be used for many purposes, including water purification, raw materials processing and the filtration of ingredients in industrial processes.

Advantages of filter housing:

The chemical cartridge filter housing is 100% made of PP (polypropylene) material, With the excellent chemical properties of PP material, the one-time injection-molded housing has no contact, no dead corners, and precise specifications; it is of high quality, high efficiency, economical and practical Excellent products.

1. The electroplating filter is especially suitable for electroplating liquid, chemical liquid, pure water circulation filtration and other purposes.

2. The use of a magnetic drive pump to ensure no leakage.

3. Filter element design, high-precision filtration, wide filtration area, high efficiency, simple operation, easy cleaning, and low cost.

4. The main body of the filter barrel of the electroplating filter is made of PVDF/FRPP.

5. Super pressure-resistant design, can withstand greater pressure without leakage.

Features:

The chemical filter housing design using injected technology. Whole piece from top to bottom without welding. The design concept adopted from integrative mold to increase the intensity of the filter body with projection rib. Injection technology prevents leakages from the filter housing body.

The material of the filter body is made from FRPP, PVDF or Transparent acrylic ,depending on the process requirements.

Filter housing can be assemble with self-priming pump or magnetic drive pump which depending on customers requirements.

These filtration is excellent application for plating operations, etching operations and other normal chemical operations.

Depending on customer’s requirement, various filter elements for selection and easy to operate:

· Lock core filter

· Pressure core filter

· Pressure Layered Core Filter

· Bag Filter

· Paper Filter

· Bellow Filter

6.The filter system provides high precision with wide area filtering, high efficiency, easy to operate and clean.

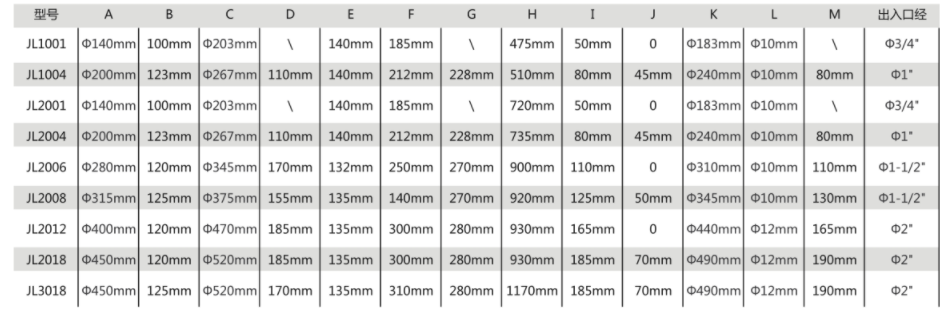

SPECIFICATION:

| Model | JL-1001 | JL-2001 | JL-1004 | JL-2004 | JL-2006-1 | JL-2008-1 | JL-2008-2 | JL-2012-2 | JL-2018-3 | JL-3018-3 |

| Applicable electrode plated tank(m³) | 0.2 | 0.3 | 0.6 | 0.8 | 1-2 | 1.5-2.5 | 2-3 | 2.5-4 | 4-6.5 | 6-7 |

| Filter capacity (L/min) | 15 | 30 | 60 | 80 | 150 | 180 | 220 | 250 | 330 | 430 |

| Core Number(size* pcs ) | 10"*1 | 20"*1 | 10"*4 | 20"*4 | 20"*6 | 20"*8 | 20"*8 | 20"*12 | 20"*18 | 30"*18 |

| Temperature | 70℃ | 70℃ | 70℃ | 70℃ | 70℃ | 70℃ | 70℃ | 70℃ | 70℃ | 70℃ |

| Weight(kg) | 16 | 18 | 29 | 35 | 71 | 78 | 82 | 98 | 118 | 126 |

| In-outlet(Inch) | ¾" | ¾" | 1" | 1" | 1½" | 1½" | 1½" | 1½" | 2" | 2" |

INSTALLATION:

PRODUCT FEATURES:

1. Filter body design using injected technology. Whole piece from top to bottom without welding. The design concept adopted from integrative mold to increase the intensity of the filter body with projection rib. Injection technology prevents leakages from the filter housing body.

2. The material of the filter body is made from FRPP, PVDF or Transparent acrylic ,depending on the process requirements.

3. Filter housing can be assemble with self-priming pump or magnetic drive pump which depending on customers requirements.

4. These filtration is excellent application for plating operations, etching operations and other normal chemical operations.

5. Depending on customer’s requirement, various filter elements for selection and easy to operate:

· Lock core filter

· Pressure core filter

· Pressure Layered Core Filter

· Bag Filter

· Paper Filter

· Bellow Filter.

6. The filter system provides high precision with wide area filtering, high efficiency, easy to operate and clean.

Application for electroplating, surface treatment, metal finishing, PCB etching equipment, pharmaceutical environmental protection, etc.